articles/Presentation/borders-page2

Imaging without borders! - part 2 of 1 2 3

by Mike McNamee Published 01/06/2013

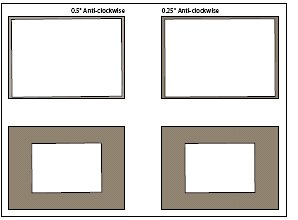

An error of 0.5° is easy to see regardless of the border size. At 0.25° the small border shows the error but the large border is starting to hide the efffect.

The notion of pushing an image size right up to the edge of a window seems to be a 'photography' thing, an observation confirmed by Dave Davies - STOP DOING IT! Look at the images on the right, the wide border has quite an influence - and that's before we have time to admire a nice watercolour paper!

Even so we went ahead and measured the skew of images on A2 sheets on two 3880s and a 4900 (all Epson). We also used Epson Traditional Photo Paper, Epson Signature Worthy Cold Pressed Bright White Paper and a 200gsm Tecco Fogra proofing paper (in roll form).

The outcome of our deliberations is as follows: 0.5° Anti-clockwise 0.25° Anti-clockwise Epson TPP is a stiff and heavy paper which is most likely to cause issues especially if loaded into the front sheet feed tray of the 3880. The skew amounted to 3mm on the long edge of an A2 print. Feeding CPBWP through either the rear sheet loader or the front manual tray produced skew errors around 1mm.

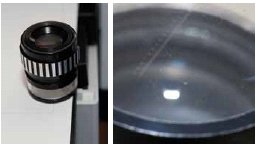

The corner of a 16x20 inch image set on a 17x22 inch paper size. The positioning of the print on the page moves from right to left depending on the loading method, the errors in positioning across the printer are shown up and down on the page. The skew errors have to be measured at each end of the print and are not shown, only noted.

Measurements were made with a six-element graticuled loupe to

± 0.05mm

Next we had to establish if the errors were due to out-of-shape rectangles or simply right-angled rectangles set to the page on an angle. This is important. Assuming the window is truly squared off, then as long as the live matter of the image is square then all will be well. Measuring angles is a difficult task, it has always been so in engineering metrology. However, when a print is truly square-cornered then the diagonals are of equal length and we can measure this to about ± 0.5mm. The skewness to the edge of a print we can measure to ± 0.05mm (using a loupe graticule). We had drift of about 3mm down the length of an A2 print which represents an angle of 0.44°, small but significant. If that error were due to out-ofsquareness in the print then the variation in the diagonals would have to be 1.2mm which is inside our measuring error. In other words we can say with some confidence that the prints are square (ie with corners exactly 90°) and that the run out is due to the paper transport skewing the paper over as it moves it. Reading on the various forums people have tackled the matter in a variety of ways, including encasing the printer in a frame which holds the paper square throughout the printing. This, of course is what happens with a roll feed and so we moved onto an Epson 4900 to test this out.

Please Note:

There is more than one page for this Article.

You are currently on page 2 Contact Mike McNamee

1st Published 01/06/2013

last update 09/12/2022 14:51:51

More Presentation Articles

There are 0 days to get ready for The Society of Photographers Convention and Trade Show at The Novotel London West, Hammersmith ...

which starts on Wednesday 14th January 2026