articles/Paper/layingtrail-page8

Paper Chase - Laying the Trail - part 8 of 1 2 3 4 5 6 7 8 9 10

by Mike McNamee Published 01/04/2004

Surface texture - Textured papers are only normally used for painting, drawing, inkjet printing and letter press printing. They are difficult to use with Offset Litho printing, the type used to print this magazine. When we use the term art paper we really mean fine art i.e. intended for painting and creative imaging.

The texture or tooth of the paper is a key element in giving it its feel. A size is usually applied to keep the inks or paints close to the surface. A traditional watercolour paper is often prepared for use by wetting and stretching it out to dry. Some people make paper as a hobby in its own right. This is very ancient technology stretching back to Egyptian times and papyrus (from whence the name paper is derived). Most of the quality art papers come off a mould machine rather than the Fourdrinier machine used to make huge rolls of paper. The mould machine makes rolls of paper but has a woolen felt that presses the output against the drying rollers and imprints its own unique signature to the paper. As the felt wears the texture of the paper becomes less pronounced. Other materials may be substituted for the wool felt which also imparts different characteristics. There are reckoned to be only about six mould making machines in the world, so it is hardly surprising that many papers share the same base paper. The subsequent coating process has a great influence on the final result though.

Coating Technologies - Coating is a very new area for things like inkjet printing and this is where the trouble begins! An inkjet relies on squirting a very tiny drop of ink onto the page. By tiny we mean as low as 3 pico litres. This is a very small drop indeed, you would need 34 million of them to fill a thimble. Even at the 30,000 drops per second this would take the printer well over an hour to fill the thimble - scary! In terms of spatial resolution, a new Epson spits 2880 drops in an inch run of image. The last thing that they want is for this ink to run about all over the place thus destroying their carefully arranged dot pattern. This is where the fun gets going in earnest. You have to prevent the ink running straight down the microscopically sized holes in the paper surface and out into the body of the paper. That is what happens if you print onto a photocopy paper and the result is a dull lifeless image. If you then decide to coat the paper with an impenetrable layer the ink will sit on the surface, smudge and resolutely refuse to dry. The trick is to take the ink off the surface but then stop it and hold it close to the surface. Even when you have achieved that aim you are not secure. The ink continues to diffuse into the surface overnight and the print does not look the same in the morning. Even if it does, it may still be subject to long-term migration. As if this is not enough, the different inks diffuse at different rates depending upon their chemical properties.

A number of different coating technologies are now available to the paper maker. The problem for the user is the advertising men. In a desperate search for market advantage they have (as ever) ruthlessly twisted and hyped the printjargon until you just have no idea what type of paper/coating combination is before you. Their copy is littered with words like, micro, nano and pico and (wait for it !) - meso has recently appeared. Micro is a millionth, nano is a thousand-millionths, meso is between nano and micro (meso is Latin for between). So now you can have a porous coating described as microporous, but when sales slump it goes up to nanoporous and if you want to show your Latin roots you go for mesoporous!

There are a number of paper and paper coating combinations is common use. Most of them make use of the mineral Rutile, which is Titanium Dioxide Ti02 a very white powder when it is ground up. It should not be confused with titanium golf drivers or hip replacement joints, they use the pure metal as a casting material. Titanium Dioxide is used for all sorts of applications which require whiteness. Your white PVC windows for example (on your house not your PC) are a PVC loaded with Titanium Dioxide. This version is very clever as it consists of little balls of Titanium Dioxide coated first in a shell of Silicon Dioxide then an Aluminium Oxide shell and then an organic surface coating. Discovered in 1913, titanium dioxide is a ceramic and is frequently mixed with other ceramics and minerals when used as a coating medium. When a coating is referred to as a "swellable polymer" the outer coating of the ceramic balls is most likely coated with a Hydrophilic Additive (hydrophilic means water swellable).

For coatings you have a choice of four technologies

1. Cast Coated

2. Swellable Polymer

3. Microporous (meso porous, nanoporous)

4. Infusion Coated

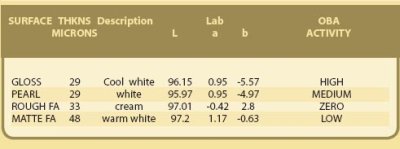

Many matte papers are cast coated. Examples of swellable polymer are Epson ColorLife and Ilford Galerie Classic. Microporous coatings are used in conjunction with Resin Coating (RC) in Ilford Galerie Classic papers and Epson Premium Lustre. At the moment the only infusion coated paper we are aware of is the St Cuthbert Bockingford fine art paper. The overall characteristics of papers are shown in the table. Art paper requirements are governed by the expectations of artists and fine art publishers. The Fine Art Trade Guild (FATG) requirements are listed in the table as an example.

Life Issues - The advantage that swellable polymer has is that the swelling of the coating seals the surface and reduces the ingress of airborne chemicals (principally ozone and water vapour). This helps to improve fade resitance. Perversely, the down side is that the small scale of the surface porosity will sometimes reject the larger particled, pigment materials, flood more easily or not dry at all. For a dye ink, swellable coating last between 2 and 3 times longer (from c8 years out to c25 years). However, pigment inks always outlive dyes.

The Wilhelm Imaging research results indicate lives of >100 years for Epson 2000 inks, 62 years for the hybrid pigment/dye Ultrachrome inks on Somerset Velvet. Interestingly, the addition of a coating to the latter test pushes the result out to >145 years.

Please Note:

There is more than one page for this Article.

You are currently on page 8

- Paper Chase - Laying the Trail page 1

- Paper Chase - Laying the Trail page 2

- Paper Chase - Laying the Trail page 3

- Paper Chase - Laying the Trail page 4

- Paper Chase - Laying the Trail page 5

- Paper Chase - Laying the Trail page 6

- Paper Chase - Laying the Trail page 7

- Paper Chase - Laying the Trail page 8

- Paper Chase - Laying the Trail page 9

- Paper Chase - Laying the Trail page 10

1st Published 01/04/2004

last update 09/12/2022 14:55:40

More Paper Articles

There are 0 days to get ready for The Society of Photographers Convention and Trade Show at The Novotel London West, Hammersmith ...

which starts on Wednesday 14th January 2026