articles/Printers/asking-page1

ASKing all the right questions - part 1 of 1 2 3 4

by Mike McNamee Published 01/08/2007

Although inkjets tend to occupy more editorial pages in Professional Imagemaker, we are aware that there are photographers out there who are making some serious money from capitalising on the robustness, speed and flexibility of the dye sublimation printing technologies.

Dye Sublimation (dye sub) is a radically different technology to either piezo- or bubble- inkjet. For starters, there is no liquid ink. Secondly, because it is a continuous tone process (contone) there is no need for multiple firings of dots to get graduated tones and smooth transitions.

Thirdly, the speed is only limited by how fast you can drag a piece of paper and donor-foil through a machine and get the heat in. All this magic works because of sublimation.

This is a physical process in which a liquid is transformed into a gas without going through the normal, intermediate stage, of being a liquid. Other materials sublimate, with perhaps the most common being iodine - the iodine you get from your pharmacist is dissolved in ethanol, the pure chemical is a subliming solid.

The 'ink' of the dye sub is carried on a donor sheet in three or four repeating sections coated with cyan, then magenta, then yellow dyes and finished (sometimes) with a varnish-like material to make the print more robust. This is why you see the media whizzing back and forth through the printer three or four times, with the print changing colour each time it pops out, until the final time. It is also why all dye subs use identical amount of media for each print (of the same size). If the image has a white surround, all the dyes in that area of the image stay on the donor sheet, and are carried through unused. The outflow from this is identical cost-per-pop, and also an absolute knowledge of how many prints you are going to get from a roll, before you need to change it.

Overall then the advantages of dye sub are speed and the fact that you can put the printer on the car seat without any danger of getting ink on the upholstery! The speed advantage we will come to next.

For some applications, speed is essential. Imagine shooting a gala dinner with 500 guests. Give or take, that would involve 250 couples, plus another 50% of group shots of pals who arrive together. In the round you are looking at 400 shots. Now, assuming that the dinner takes 90 minutes, you are going to have to get in there with your 400, sleeved-up prints and start taking money from the merry throng before they either leave, or pass out - you have to get them while they still have money or can still remember their PIN number! Four hundred prints in 90 minutes equals 13.5 seconds per print. The ASK 2000 does 6x4s in 8 seconds, the ASK 4000 does 10x8s in 40 seconds - have we made the point? Printing for this type of photography has got to be fast - very fast! The rewards, though, can be considerable, it is not called 'Flash, Cash and Dash' for nothing - some photographers are coming away with thousands in their pockets (and they earn it in my book!).

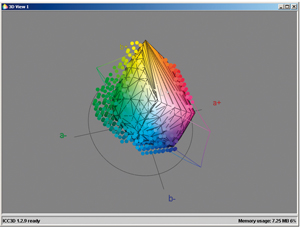

Against a backdrop such as this, things have to be very simple, you cannot be agonising over which rendering intent to use or how much sharpening to apply to an image. The printer driver must be quick and slick. Despite this we went about our testing in our usual methodical manner. The only compromise we made was to hand-measure the audit charts, they were too small for the automatic specro!

You are currently on page 1

- ASKing all the right questions page 1

- ASKing all the right questions page 2

- ASKing all the right questions page 3

- ASKing all the right questions page 4

1st Published 01/08/2007

last update 09/12/2022 14:51:20

More Printers Articles

There are 0 days to get ready for The Society of Photographers Convention and Trade Show at The Novotel London West, Hammersmith ...

which starts on Wednesday 14th January 2026